ENTERPRISES, INC.

HOME![]()

ENVIRO - BOND ™

ENVIRO - BOND ™ FAQ.

VIDEO.

BILGE SOCKS.

SAFETY SEAL.

CONTAINMENT BOOM.

DRAIN PROTECTOR ®

PRODUCTS.

DOCUMENTS.

ORDER .

E-MAIL .

BUZZARDS BAY

REPORT ON

BILGE SOCKSMASSACHUSETTS

COASTAL ZONE

MANAGEMENT

BILGE SOCK LETTERCHEMICAL

COMPATIBILITY

TEST

LAKEFRONT ENTERPRISES, INC.

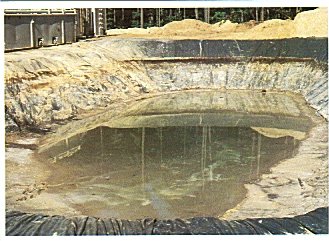

It's a fact! Waste from drilling operations has became very expensive and environmental regulations have caused many wells not to be drilled. That is why we researched and developed the Super Polymer product line. While many other companies developed mechanical equipment and more expensive operations, we merely used chemistry to achieve better results, at lower costs, with many cost saving benefits and with products that are environmentally safe. Drilling fluids are complex structures We took the approach that if chemistry could put them together, then chemistry would take them apart. Today we can effectively dewater many drilling fluid structures and, by doing so, the volumes are substantially reduced. All of our products have been field tested, in conventional and closed systems, in many states for both major and independent companies.

|

|

|

|

|

|

|

| Conventional:

This well was drilled directionally to a depth of 6,350 feet with a second directional bottom hole. The fluids were both fresh and saturated with salt water. The polymers were used after the reserve pit was full of very dirty drilling fluid. The fluid was pretested, and the proper amount of polymer was then applied. Within 30 minutes clean fluid was returned to the drilling operation. By pre-planning this drilling operation, thousands of dollars could have been saved by generating less water, smaller reserve pit, less liner, and excavating. Fifty percent solids were generated and was stabilized with less material. |

Closed System:

This well was drilled to a depth of 6,100 feet with both fresh add saturated salt water. No solids control equipment, only a shale shaker (shaker optional for samples). All solids were settled in the closed loop (average 37% within 24 hours). The super polymer was used to control solids. All clean fluids were disposed of immediately after drilling in a disposal well. |

|

|

|

| ENVIRO-BOND ™ 100 Series super polymers require NO pre-wetting, expensive mixing systems, will not affect Water loss or viscosity building polymers, while selectively settling solids | |

|

|

|

| ENVIRO-BOND ™ has a proven track record of savings to drilling operation and solids management. | |

|

|

LAKEFRONT ENTERPRISES, INC.

P.O. Box 573, North Hampton, NH 03862

Tel: (603) 964-2740 Fax: (603) 964-2739

E-Mail: berquist@enviro-bond.com

Web: www.enviro-bond.com